Vision The Future: 3D Printing and Technology at S.A. Engineering College

- Posted by S.A.E.C

- Categories 3D Printing

- Date December 1, 2024

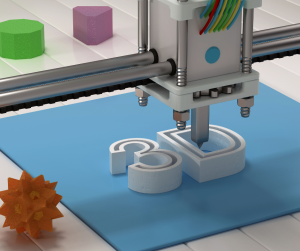

In today’s fast-evolving technological landscape, 3D printing has emerged as a game-changer, revolutionizing industries and reshaping how we approach manufacturing, design, and innovation. Known as additive manufacturing, this technology enables the creation of three-dimensional objects by layering materials based on a digital model. At S.A. Engineering College, we recognize the immense potential of 3D printing and are committed to fostering innovation in this exciting field.

This blog explores the fundamentals of 3D printing, its groundbreaking applications, and its future potential. Let’s delve deeper into this transformative technology and understand its role in engineering education and beyond.

Understanding 3D Printing Technology

3D printing is the process of creating a physical object from a digital design. It uses materials such as plastics, metals, ceramics, or even bio-materials, layering them in precise patterns to build intricate shapes and structures. Unlike traditional subtractive manufacturing methods, which carve out a product from a larger material block, 3D printing builds objects layer by layer, resulting in minimal waste.

Key Components of 3D Printing

- 3D Modeling Software: The design begins with CAD (Computer-Aided Design) software, where engineers draft the digital model of the object.

- Printing Materials: Depending on the application, materials can range from thermoplastics like PLA and ABS to advanced alloys and composites.

- 3D Printer: A machine equipped to execute the layering process with precision, powered by technologies like Fused Deposition Modeling (FDM), Stereolithography (SLA), or Selective Laser Sintering (SLS).

Why is 3D Printing a Game-Changer?

The versatility and precision of 3D printing have opened up new possibilities across various fields. Below are some of the reasons it stands out as a groundbreaking technology:

- Cost Efficiency: It reduces material wastage and eliminates the need for expensive molds and tools.

- Customization: Tailored designs can be manufactured quickly, making it ideal for healthcare, aerospace, and art industries.

- Speed: Rapid prototyping enables industries to experiment, modify, and finalize designs within days instead of weeks.

- Complex Geometry: It allows the creation of structures that are difficult or impossible to achieve through traditional methods.

- Sustainability: With reduced waste and the possibility of using recycled materials, 3D printing contributes to greener manufacturing practices.

Innovative Applications of 3D Printing

- Aerospace and Automotive Engineering

In the aerospace industry, 3D printing is used to fabricate lightweight yet robust parts, such as engine components and turbine blades. Similarly, automotive giants utilize this technology for prototyping, designing custom components, and even crafting entire car chassis.

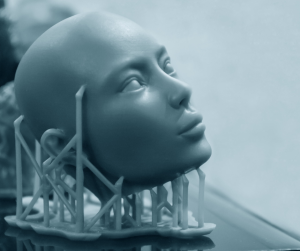

- Medical Advancements

From prosthetics to organ bioprinting, 3D printing has transformed healthcare. At the forefront are innovations like patient-specific implants, custom surgical tools, and even artificial skin. Researchers are now experimenting with printing human tissues using bio-ink made from stem cells.

- Construction

3D printing is reshaping construction with the ability to create entire homes and buildings. The use of concrete 3D printers has drastically reduced construction costs and time while paving the way for sustainable architecture.

- Education and Research

At institutions like S.A. Engineering College, 3D printing serves as a vital educational tool. It allows students to materialize complex ideas, explore innovative designs, and undertake research that pushes the boundaries of conventional engineering.

- Fashion and Art

Fashion designers leverage 3D printing to craft unique clothing, jewelry, and accessories. Artists use it for sculpting intricate designs, adding a technological edge to traditional craftsmanship.

Rare and Emerging Segments in 3D Printing

While the above applications are widely recognized, several emerging and lesser-known areas of 3D printing hold immense promise:

- Food Printing

Imagine printing gourmet meals at the press of a button! Food printing is an exciting innovation where edible materials such as chocolate, dough, or pureed ingredients are used to create culinary masterpieces. It has significant implications for personalized nutrition and space travel.

- 4D Printing

Building on 3D printing, 4D printing involves materials that can change shape, color, or properties over time in response to environmental stimuli like heat, water, or light. It has potential applications in smart textiles, adaptive furniture, and self-healing structures.

- Pharmaceutical Printing

3D printing has entered the pharmaceutical industry, where medications are being printed in precise doses tailored to individual patients. It ensures accuracy and personalization, enhancing drug efficacy.

- Environmental Conservation

3D printing is being used to address environmental challenges, such as creating artificial coral reefs to support marine life and developing biodegradable materials to reduce plastic pollution.

3D Printing at S.A. Engineering College

At S.A. Engineering College, we pride ourselves on equipping students with cutting-edge knowledge and hands-on experience in technologies like 3D printing. Our state-of-the-art labs, expert faculty, and industry collaborations ensure that students are well-prepared to thrive in this evolving field.

Educational Initiatives

- Workshops and Seminars: Regular events introduce students to 3D printing fundamentals, advanced techniques, and industry applications.

- Lab Facilities: Our dedicated 3D printing labs provide students with access to the latest equipment, enabling them to experiment and innovate.

- Project-Based Learning: Students undertake projects involving real-world applications of 3D printing, such as prototyping mechanical parts or creating artistic models.

Collaborations with Industry

We collaborate with leading companies and research organizations to provide internships and research opportunities. This bridges the gap between theoretical knowledge and practical application, ensuring our students remain industry-ready.

Challenges and the Future of 3D Printing

Despite its numerous benefits, 3D printing faces certain challenges:

- High Initial Costs: Advanced printers and materials can be expensive, limiting accessibility for small businesses and individuals.

- Material Limitations: Not all materials are compatible with 3D printing, and the durability of printed objects may sometimes fall short.

- Skill Gap: Effective use of 3D printing requires specialized knowledge, emphasizing the need for robust educational programs.

Looking ahead, 3D printing is poised to become even more versatile and widespread. Innovations in materials, speed, and scalability will drive its adoption in industries like space exploration, where NASA is already experimenting with 3D-printed habitats for Mars.

Conclusion: The Future is in Your Hands

3D printing is more than just a manufacturing tool—it’s a gateway to boundless creativity and innovation. At S.A. Engineering College, we believe that empowering our students with this transformative technology is key to shaping a better tomorrow. Whether it’s through designing life-saving medical devices, pioneering sustainable architecture, or reimagining everyday products, the possibilities are endless.

Ready to explore the world of 3D printing? Join S.A. Engineering College, where technology meets ingenuity.

To learn more about our engineering programs and facilities, visit saec.ac.in, email us at saec@saec.ac.in. Your journey toward innovation begins here!

You may also like

3D printing, also known as additive manufacturing, is revolutionizing various industries, including education. By enabling the creation of tangible objects from digital designs, 3D printing opens up a world of possibilities for students and educators alike. This technology enhances learning …